MECHANICAL PROPERTIES OF METALS

MECHANICAL PROPERTIES OF METALS

1 . The mechanical properties are those which are associated with the ability of the material to resists mechanical forces and loads .

2 . These mechanical properties are metal include strength , stiffness , elasticity , plasticity , ductility , brittleness , malleability , toughness , resilience , creep , hardness .

There are some properties of metals which given below :-

1 . STRENGTH :-

It is the ability of the material to resits the external applied force without breaking or yielding . The internal resistance offered by a part to an externally applied force called stress .

2 . STIFFNESS :-

It is the ability of the material to resists deformation under stress . The modulus of elasticity is the measure of stiffness .

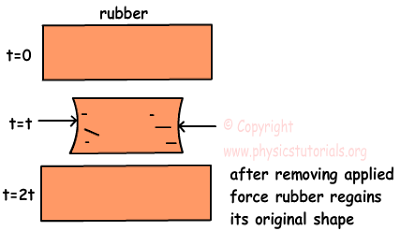

3. ELASTICITY :-

It is the properties of material to regain its original shape after deformation . when the external force is removed.

4 . PLASTICITY :-

It is the properties of material which retain the deformation produced under load permanently .

5 . DUCTILITY :-

A dctility material must be both strong and plastic . The ductility is usually measured by the terms percentage elongation and percentage reduction in area . The ductile material commonly used in engineering practice . like steel etc .

6 . BRITTLENESS :-

It is the properties of a material opposite to ductility . It is the properties of breaking of a material with little permanent distortion . Brittle material when subjected to tensile load , Cast iron is a brittle material .

7 . MALLEABILITY :-

It is a special case of ductility which permits material to be rolled or hammered into thin sheets . A malleable material should be plastic but it is not essential to be so strong .

8 . TOUGHNESS :-

It is the material to resists fracture due to high impacts load like hammer blows . The toughness of the material is decrease when it is heated . It is measure in amount in which that a unit volume of the material has absorbed after being stressed upto the point of fracture .

:9 . MACHINABILITY-

It is the properties of a material which refers to a relative case with which a material can be cut . The machinability of a material can be measure in a number of way such as comparing or thrust require to remove the material at some given rate .

10 . RESILIENCE :-

It is the properties of a material to absorb energy and to resists shock and impact loads . It is measured by the amount of energy absorbed per unit volume with in elastic limits .

11 . CREEP :-

When a part is subjected to a constant stress at high temperature for a long time , it will undergo slow and permanent deformation . called creep .

12 . FATIGUE :-

When a material is subjected to repeated stresses , it fails at stress below the yielding point stress . it is called fatigue . The fatigue is caused by means of a progress crank formation which are usually fine and of microscope size .

13 . HARDNESS :-

It means the ability of a metal to cut another metal . The hardness is usually expressed in numbers which are dependent on the method of making the test .

No comments:

Post a Comment